When you want to control the speed of a motor, one of the first controls that come to mind is a potentiometer. Potentiometers let you continuously adjust a setting by allowing you to choose any point between two extremes, usually an upper and lower limit. A potentiometer works by balancing electrical resistance between different points in a circuit. When the wiper moves from one terminal toward another, current flows through a varying amount of resistance. The result is that voltage at the terminals changes and triggers an output response from another part of the circuit. Potentiometers are frequently used as speed controls for dc motors because they provide precise and continuous speed control at low cost and with minimal effect on motor torque or performance. In this article, we look at how to wire a potentiometer for motor speed control.

How To Wire A Potentiometer To Control Motor Speed

- A potentiometer is a variable resistor. A variable resistor is a device that can be set to any value between two points by moving the wiper arm. The two points are often labeled as “high” and “low.” When the wiper is moved from one point to another, current flows through a varying amount of resistance. The result is that voltage at the terminals changes and triggers an output response from another part of the circuit.

- Potentiometers come in many forms, but most commonly in the form of a three-terminal device, with two terminals for input and one for output. This type of potentiometer has one wiper arm and two fixed arms (the sides). Each fixed arm has a fixed resistance that is independent of any movement on the wiper arm (and vice versa).

- Potentiometers are used with motors because they allow you to select any range between high and low, often an adjustable range between 0% and 100% or some other range. The most common applications are for controlling motor speed and direction, although they can be used for a wide variety of applications.

- A potentiometer has two terminals, one for input and one for output. When you attach a potentiometer to a motor, the wiper arm is attached to the input terminal, and the fixed arms are attached to the output terminals.

- The two points where you can set the potentiometer are typically labeled as “high” and “low”. When the wiper moves from one point to another, current flows through a varying amount of resistance. The result is that voltage at the terminals changes and triggers an output response from another part of the circuit.

- Potentiometers can be used with dc motors because they provide precise and continuous speed control at a low cost with minimal effect on motor torque or performance (although there are other ways to control speed). Potentiometers work by balancing electrical resistance between different points in a circuit (see above).

- Potentiometers are used with dc motors because they allow you to select any range between high and low, often an adjustable range between 0% and 100% or some other range. The most common applications are for controlling motor speed and direction, although they can be used for a wide variety of applications.

How A Potentiometer Works

- A Potentiometer is a two-terminal (usually three terminal) electronic circuit. The wiper is the variable resistor. The wiper makes contact with either the upper or lower terminals and moves between them over time. The output is the voltage at the other terminals.

- A Potentiometer works by balancing electrical resistance between different points in a circuit. When the wiper moves from one terminal toward another, current flows through a varying amount of resistance.

- The result is that voltage at the terminals changes and triggers an output response from another part of the circuit, such as a relay or motor controller, in order to control motor speed or position sensing for use with microcontrollers and other circuits such as Servos for example.

- Potentiometers are frequently used as speed controls for dc motors because they provide precise and continuous speed control at low cost and with minimal effect on motor torque or performance.

- In this article, we look at how to wire a potentiometer for motor speed control.

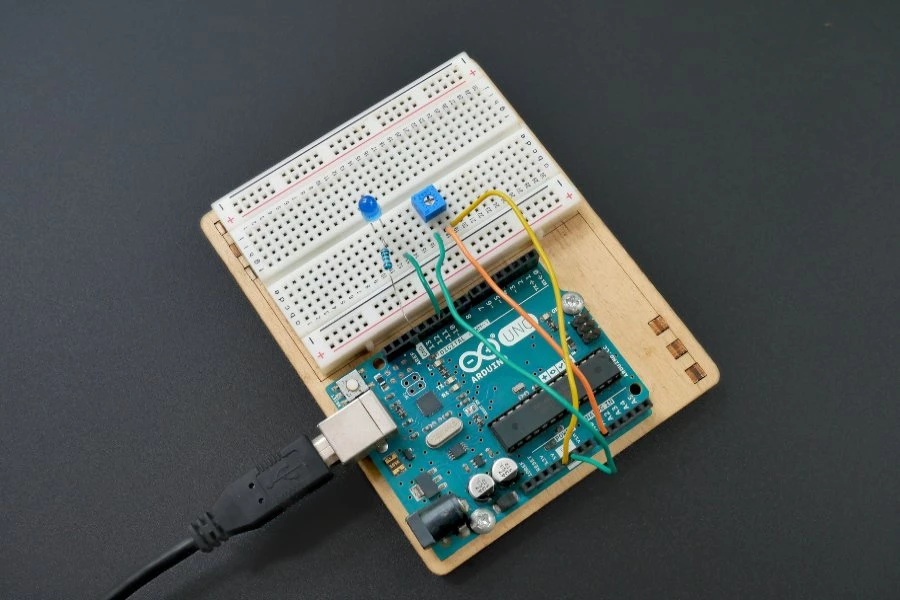

- How to Wire a Potentiometer for Motor Speed Control Potentiometers are fairly easy to wire for motor speed control and can be used with the Arduino and other microcontrollers that have built-in PWM (pulse width modulation) capability. The Arduino’s analogWrite function is a very simple way to implement the potentiometer’s wiper and trigger signals, but it is not very accurate (it tends to drift over time). A better approach is to use an analog-output shield, which uses separate PWM outputs for the wiper, trigger, and reference voltage inputs. The shield can be easily wired directly to an Arduino or other microcontroller board with built-in PWM capabilities, such as the Mega 2560 or Mega ADK. A complete circuit diagram can be found below:

Selecting The Right Potentiometer For Motor Speed Control

- Selecting the right potentiometer for your application is critical. Not all potentiometers are suitable for motor control. For example, if you want to control a dc motor at higher speeds, you need a potentiometer with more turns of wire in the wiper arm. If you want to control at lower speeds, the resistance is less important, and you can use a lower-cost potentiometer with fewer turns of wire in the wiper arm. A chart on the right shows some recommended ranges of resistance for different motor speeds.

- When selecting a pot, don’t forget that there is a difference between linear and logarithmic response curves. A linear pot (also called a rheostat) has one point on its curve that controls all possible voltages from 0 to +Vcc (the positive power supply voltage). The lower end of this range is typically +0.1V, and the upper end is typically +5V or more, depending on the pot. Logarithmic pots have a wider range between the two extremes of their curves and can be used to control voltages from 0 to 10V, or more. A logarithmic pot is usually rated for 1/10-V increments, which means that you can set the wiper arm to move from 0.1V up to 1/10-V below the positive voltage output.

- When selecting a potentiometer for motor speed control, consider whether you need a linear or logarithmic response and how many voltage levels you need to control at different speeds. For example, if you need only two different speeds (such as slow and fast), use a linear pot with a rheostat that allows adjustment of 0-5V or less on each of its wiper arms (see chart on the right). If you want three speeds (such as slow, medium, and fast), use a logarithmic pot with a rheostat that allows adjustment of 0-10V or more on each of its wiper arms.

Wiring A Potentiometer To Control Motor Speed

- Connect a potentiometer to the motor, as shown in the diagram below.

- Connect an external reference voltage to the potentiometer. The control circuit will use this voltage to vary the motor speed.

- Connect a series of resistors in parallel with the potentiometer to produce an adjustable voltage divider for motor speed control. The diagram below shows how this is done on a simple circuit, where one resistor is used for each decade of change in the potentiometer setting.

- Connect two additional resistors in series with each other and with the divider resistors.

Tips For Using Potentiometers To Control Motor Speed

- Choose the correct type of potentiometer for your application. Potentiometers come in three basic types: variable, fixed, and variable-fixed. The variable type is the most commonly used because it allows you to choose between two or more different points, while the fixed type doesn’t allow this flexibility. The variable-fixed type doesn’t have a wiper movement because it uses a fixed resistor in place of the wiper arm.

- Choose an appropriate potentiometer value for your motor. Potentiometers come in values from 1kΩ to 100MΩ (1kΩ = 1,000 ohms; 100MΩ = 100 megohms). For most applications, a value of 10kΩ is sufficient, with each 10kΩ setting providing approximately one turn of your motor.

- Make sure you know how much voltage your motor requires when using a potentiometer to control its speed. Most dc motors require a voltage of 5V to 7.5V, but some motors require as much as 12V.

- Wire the potentiometer directly to the motor’s output shaft. If you’re using a variable-fixed type of potentiometer, make sure you use an in-line resistor in parallel with the wiper arm (see Figure 2). Also, be sure to use a thick wire for connecting to the motor’s output shaft and not one that is too thin.

- Mount your potentiometer so that it can rotate freely in its mounting bracket without being tightly secured or causing vibration from wind or movement. Also, make sure you mount it so that it’s easy to access and replace when needed.

Conclusion

When you want to control the speed of a dc motor, you can use a potentiometer as speed control. When wired for speed control, a potentiometer allows you to select any speed within a range between two extremes. There are three common styles of potentiometers: railroad-type, push-pull and rotary. For motor speed control, the railroad-type potentiometer is most common, but the other styles are available and can be used in the same way. The most important factor to consider when selecting a potentiometer for motor speed control is its resistance range. You’ll want to select a potentiometer that has a minimum resistance rating that’s equal to the maximum current draw of the motor at full speed. In addition, you’ll want a potentiometer with a resistance rating that’s as low as possible at the slowest speed you want to maintain control.